A True Scissor-Neck Advantage

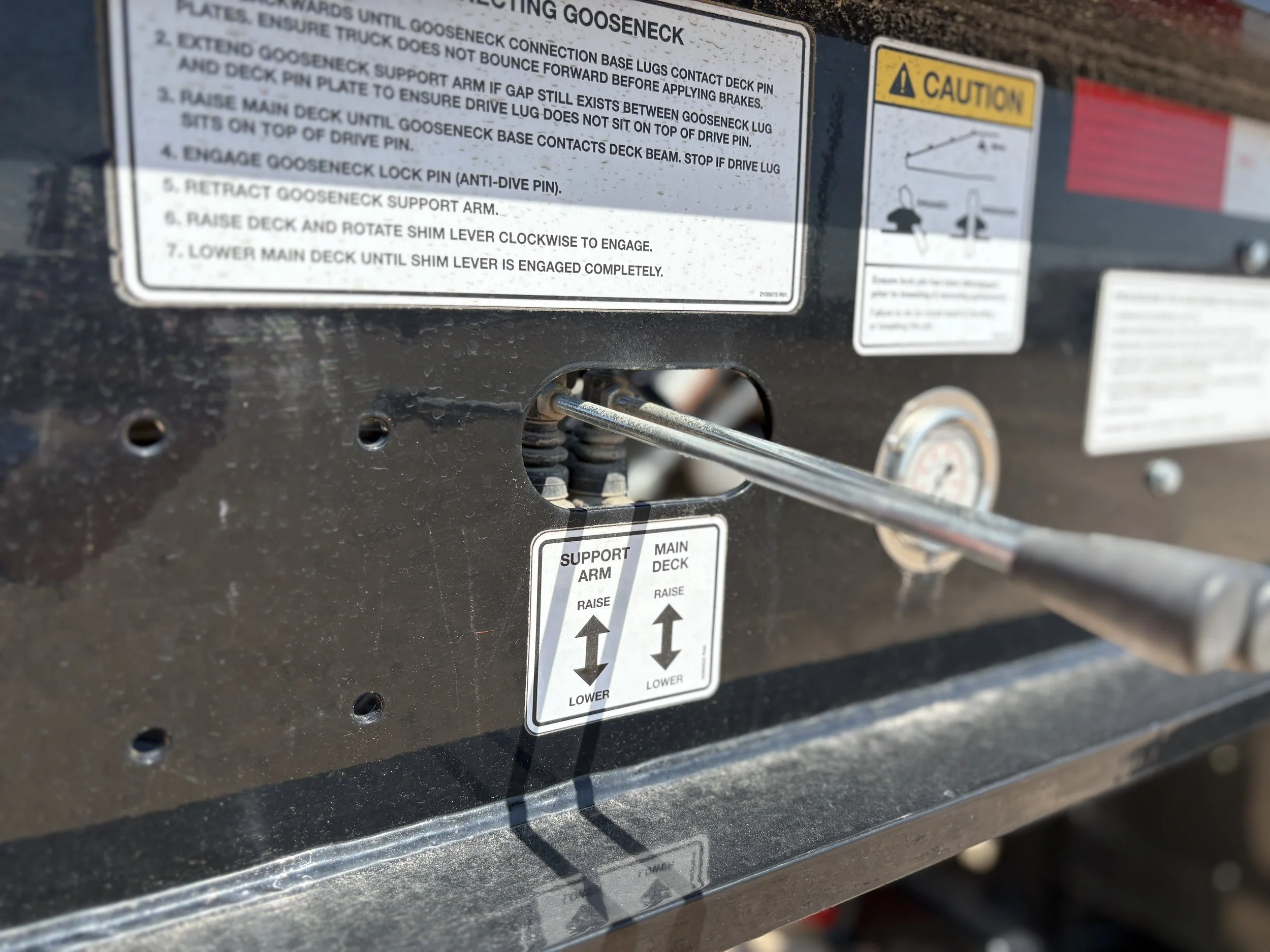

Scona’s scissor-neck design is renowned for its simplicity, strength, and ability to load heavy equipment even on uneven or soft terrain. Unlike traditional detachable-neck systems that rely on ground-bearing pads, the scissor neck lifts cleanly, stays stable, and allows smooth re-connection — even under heavy loads.

Key Benefits of the Scona Scissor Neck

Self-supporting mechanics for stable loading/unloading

Fast hookup times with minimal ground contact

Ideal for rough, oilfield, or remote jobsite conditions

Exceptional neck strength for high tongue weights

Better frame alignment when reconnecting the neck

Operators praise scissor-neck Scona trailers for their reduced downtime, lower maintenance costs, and reliability in challenging environments.

70-Ton Rated — Built to Move Serious Iron

This trailer is engineered for true 70-ton concentrated loads, giving operators the ability to move:

Large excavators

Dozers (D8–D10 class)

Crushers, screeners, and material handlers

Pipeline equipment

Rig components & pump packages

Crane pieces & counterweights

Industrial machinery

Oversized tracked equipment

Heavy-haul contractors prefer Scona because its Canadian-built frames and oversized structural members are designed for long-term abuse under the harshest conditions.

5-Axle Heavy Haul Configuration

The 5-axle setup offers the flexibility and load distribution needed for moving overweight, overdimensional equipment across state lines and varying weight regulations.

Typical advantages include:

Increased permitted capacity

Better load spreading for multi-state routing

Reduced stress on main beams and suspension

Higher resale value due to expanded hauling capability

Combined with the 70-ton rating, this configuration becomes a versatile solution that can cover a wide variety of heavy-haul missions.

Pop-Up Rollers & Tail Roller — Built for Efficient Loading

This trailer comes equipped with two high-value features rarely found on standard lowboys:

Pop-Up Rollers

Designed into the deck to assist with:

Loading low-clearance tracked machines

Sliding heavy components

Reducing deck surface wear

Lowering friction when positioning large equipment

These rollers “pop up” when engaged and drop flush when not in use — maintaining a smooth deck profile.

Heavy-Duty Tail Roller

A reinforced tail roller is built into the rear frame to:

Reduce drag when loading long-wheelbase equipment

Prevent gouging or scraping heavy machine components

Allow smoother transitions during winch-assisted loading

Extend the deck and ramp longevity

Together, these features significantly reduce operator effort and machine strain during loading.

Engineered for Strength, Reliability, and Real-World Hauls

Scona trailers are built with oversized beams, high-tensile steel, and premium North American components. Typical build advantages include:

Deep I-beam main frame designed for extreme loads

Reinforced neck pivot points with oversized bushings and pins

Crossmembers designed for heavy tracked equipment

Industry-proven suspension systems

High-capacity axles and hubs

Premium air/electrical system routing

Structural enhancements for oilfield and off-highway use

Scona’s heavy-haul platforms are respected for their ability to stay straight, resist torsional twisting, and maintain alignment over years of punishing service.

Ideal Hauling Applications

This 70-ton scissor-neck lowboy is perfect for:

Oilfield rig mobilization

Pipeline equipment transport

Mining and aggregate machinery

Heavy civil and infrastructure projects

Oversize industrial components

Crane parts and counterweights

Demolition equipment

Wind energy site support

Wherever the terrain is rough, the loads are heavy, and the work is demanding — Scona shines.

Why Heavy-Haul Operators Choose Scona

Rugged, long-lasting frames designed for extreme use

Superior scissor-neck loading unmatched by other builders

Smooth, stable detaching and reconnecting

High resale value in heavy-haul markets

Simplified maintenance with proven mechanical systems

Built for harsh climates and oilfield service

The result is a trailer that outlasts and outperforms many competing lowboys in its weight class.

Perfect for ATSR’s West Texas Customers

This Scona 70-Ton Scissor Neck Lowboy is ideal for the demanding hauling conditions found in West Texas and surrounding regions:

Soft caliche lease roads

Uneven oilfield pads

Heavy tracked equipment

Remote loading locations

Long-haul oversize permitting

Hot asphalt and aggregate environments

It brings the reliability and capability that operators in Amarillo, Lubbock, and Odessa depend on when the job simply must get done.